| EMW-History | |

|

Already 1896 created Heinrich Ehrhardt in the Thuringian iron oh the "vehicle factory iron oh" and built among other things passenger cars, which were driven out starting from 1904 under the name "DIXI". The Dixi work was taken over 1928 completely by BMW. BMW built there from now on all passenger cars and shifted motorcycle production likewise 1942 to iron oh. With end of war the work was destroyed to 60%. It aroused rapidly the interest of Soviet crew power nevertheless. Originally on 3 July 1945 expropriated and seized BMW work should to be dismantled. The commander in chief of the Soviet zone, marshal Schukow, decided however differently: It arranged the building of 3,000 motorcycles each and passenger car per year. The Soviets had acquired already before the war BMW licenses and were very much done of the reliable vehicles from Munich and iron oh. Starting from November 1945 the 350ccm-Einzylindermaschine "R 35" was built. R 35 in Munich Milbertshofen until 1940, afterwards one had been produced machine tools and spare parts for this machine after iron oh had paged out. |

|

|

|

AWTOWELO-BMW/SAG R35/2 without rearsprings |

|

The BMWs R 35 1937 from the popular a cylinder

machine "R 4" had been developed and were

based constructionally in the early 30's. At that time

press steel frameworks were modern, so that R 4 a rigid

"Blech" framework received, which inherited R

35. In contrast to R 4 an friction-absorbed

teleskopgabel possessed starting from 1937 built R the

35. The 1:6 consolidating ohv engine with 72 mm of

drilling and are enough 84 mm stroke carried out bullige

14 HP with 4.500/min. In typical BMW building method the

machine was laid out as transverse runners. In the left

part of the crankshaft housing a tool subject was

accommodated. The engine sat to the right transferred in

the framework, and the crankshaft with a sliding and a

ball bearing aligned with the cardan shaft to the rear

wheel. Between them were a trockenkupplung and a

handswitched fourgearbox, whose shift lever in the

h-pattern was led according to kind of automobile in a

window blind in the right knee cushion. The direct

current generator supplied ignition, battery and

consumer with 75 Watts.

|

|

|

|

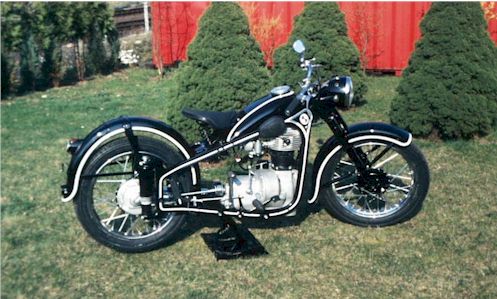

EMW R35/3 with rearsprings |

|

First entire production went as Reparationsgoods into

the Soviet Union. This modest production was the

reopening of the building of motorcycles in Central

Germany. The Eisenacher BMW work was converted on 15

September 1946 into a national corporation into Soviet

possession, and firmierte from now on as "individual

enterprise BMW of the Soviet corporation (SAG)"

"Awtowelo". Conditions stabilized nevertheless

so far that already 1946 about 1,300 and in the

subsequent year already more than 2,500 R 35 could be

delivered. Two years later, in the year of the

foundation of the GDR, rolled over 4.000 R 35 of the

assembly-line. Still with BMW emblem at the tank, now

the first machines arrived into the normal sales.

|

|

|

|

Promotion for EMW R35/1 from 1948/1950 |

|

Starting from 1951 the red-white EMW emblem shines on the frame of the generally black machines. BMW had complained against the use of its brand name and had won, so that out BMW say iron oh EMW became. Until since the new beginning more than 25,000 R 35 the Eisenacher manufacturing plant had left end of the yearly. The simple concept of the machines had itself as gold correct proven, only the primitive chassis was on the GDR plaster runways a problem. Thus R appeared 35 1952 with hydraulically absorbed teleskopgabel and foot in place of handschaltung. In addition the machine starting from chassis number 256,000 side car fitness certified, here good practical experiences spoke the judgement with the durable machine. This series are to be regarded as transition model and ran 8.000-fach from the Eisenacher volume. In the same year, i.e. in June, the work became from the Soviet corporation to dismiss and the state-owned enterprise "VEB IFA car factory EMW Eisenach" (EMW).

|

|

|

|

EMW R35/3 with rearsprings |

|

1953 were reduced the number of the protective pipes

at the cylinder head to two and - which was more

important - the framework received an oil-absorbed

rearspring for the rear wheel. R 35/3"machine

mentioned built the Thueringers still about 58,000 times,

before in April 1956 production was stopped, in order to

create more capacities for the automotive manufacture.

by Andy Schwietzer |

|